Moody's Diagram (or Moody's Chart)

|

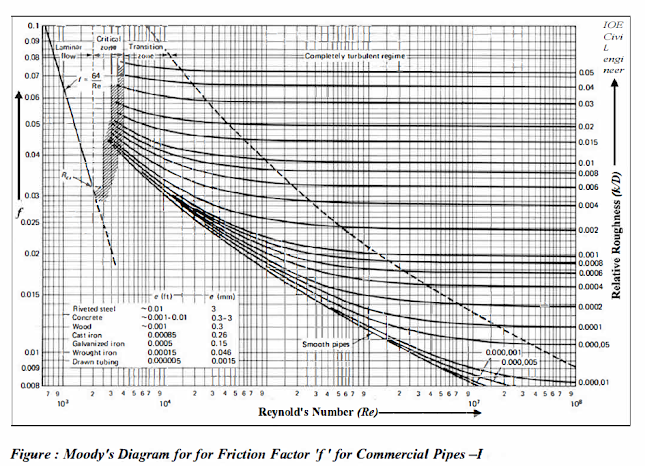

| Fig: Moody's diagram for the friction factor 'f' for commercial pipes-I |

The value of Equivalent sand grain roughness (k)' given in

Table 1-2 correspond to material in new and clean condition. As the pipe become

older, the roughness increases may increase with time in accordance with

following expression

Where, k= Equivalent sand grain roughness at any time 't', Equivalent sand

grain roughness of new pipe material and a = Time rate of increase of

roughness.

Salient features of Moody's Diagram

a) Laminar flow (Re<2000)

Friction factor (f) is a function of 'Re' only

b) Critical zone (2000<Re<4000)

Flow in this zone is either laminar

or turbulent (i.e. oscillatory flow that alternately exists between laminar and

turbulent flow). There is no any specific relationship between 'f 'and 'Re' in this zone.

c) Transition zone (Re>4000)

For 'k/D < 0.001 ' and certain

ranges of 'Re' in this zone, the roughness elements are submerged in the

viscous sub-layer, and the flow can be considered to be smooth pipe flow. In

this zone, T is a function of both 'Re' and 'k/D'.

d) Complete turbulent zone (Re>4000)

In this zone, average

roughness height is substantially greater than the viscous wall layer

thickness. As 'Re' is high, the head loss is also higher due to the extra

turbulence caused by projections. The friction factor (f) is a function of 'k/D' only and is independent of 'Re'. The horizontal lines indicate that friction

factor (D does not change with 'Re', that means viscosity does not affect the

head loss in this zone.

Determination of Value of 'f' from Moody Chart:

(i)

Mark the value of 'Re' =VD/v on the abscissa (i.e. Re - axis)

(ii) For the given value of 'k/D', mark the point of intersection of 'Re' with 'k/D'. To find the intersection point, draw vertical line from 'Re' and follow curve path from 'k/D'. If 'k/D' curve is not available for given value of 'k/D', draw a curve by following the trend of nearby curve.

iii) Draw a horizontal line from the point of intersection of 'Re' and 'k/D' to ordinate (i.e. f- axis)

(iv)

Finally, read the value of friction factor (D

from the chart.

Flow chart of Friction factor (f)

- Pipe flows and open channel flows in Hydraulics

Reynold's Experiment | Laminar flow's in circular pipe | Shear stress distribution

Interception and Interception losses

Turbulent Flow | Velocity and shear stress in turbulent flow

Reynold's Theory | Prandtl mixing length Theory

Hydrodynamically smooth and rough boundaries | Velocity distribution for turbulent flow

Nikuradse experiment | variation of frictional factor (f) for laminar and turbulent flow

Minor head losses in pipes | Equivalent length of pipe representing minor head losses

Comments

Post a Comment