Velocity distribution in smooth pipes

In the vicinity of a smooth boundary there exists a laminar sublayer. The flow in the laminar sublayer being laminar has a parabolic velocity distribution. Since the thickness of laminar sublayer (δ') is generally very small, the parabolic velocity distribution in the region may be approximated by a straight line without appreciable error.

So, in the zone of laminar sublayer, since the flow is laminar, the viscous stress predominates and the turbulent stresses tend to become zero. Therefore, in the laminar sublayer, the shear is

For linear velocity distribution within the laminar sublayer, 'du/dy' becomes 'u/y'.

Ad:

|

| Fig: Velocity distribution for turbulent flow near a smooth boundary |

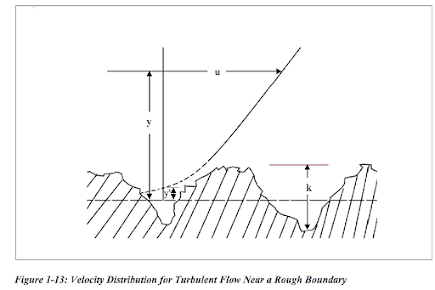

Velocity distribution in rough pipes

|

| Fig: Velocity distribution for turbulent flow near rough boundary |

Ad:

- Pipe flows and open channel flows in Hydraulics

Reynold's Experiment | Laminar flow's in circular pipe | Shear stress distribution

Interception and Interception losses

Turbulent Flow | Velocity and shear stress in turbulent flow

Reynold's Theory | Prandtl mixing length Theory

Hydrodynamically smooth and rough boundaries | Velocity distribution for turbulent flow

Nikuradse experiment | variation of frictional factor (f) for laminar and turbulent flow

- Determination of Value of 'f' from Moody's Chart

Minor head losses in pipes | Equivalent length of pipe representing minor head losses

Comments

Post a Comment